Sale

De.Ma produces SACO-type attachments for multi-spindle lathes of the best brands such as Gildemeister, Wickman, Schütte, Tornos, Mori-Say and Index.

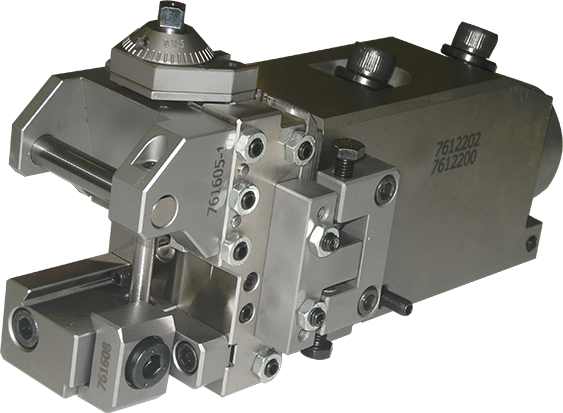

Broaching attachment

In case the production of a particular piece requires to broach polygons inside or outside the piece the adopted solution is generally a broaching attachment (at the condition that the polygons are reachable from the front). The tool rotates synchronously to the piece and the specific cam for broaching controls the attachment movement.

The De.Ma range of broaching attachments for multi-spindle lathes includes the ones for Wickman. Gildemeister. Schutte, Mori-say and Tornos automatic lathes.

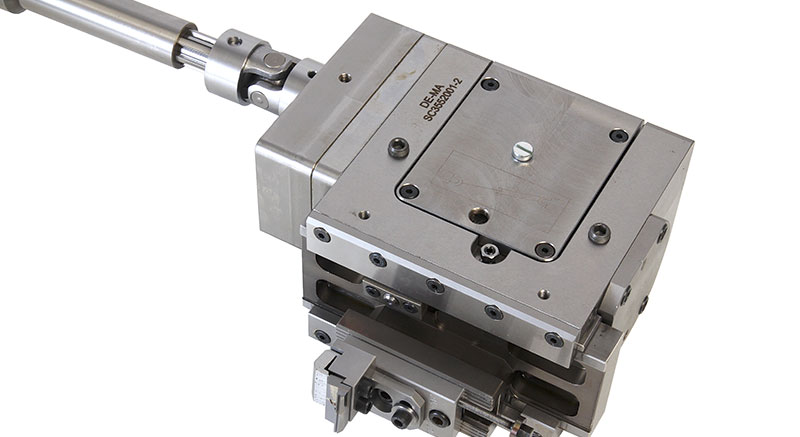

Shaving attachment

Turning of cylindrical or shaped surfaces on pieces that rotate on the main spindle on multi-spindle lathes is generally obtained by a shaving attachment. This equipment is particularly suitable for obtaining diametric turnings with narrow tolerances, which generally anticipates subsequent machining operations such as thread rolling (which, in fact, requires high precision). The De.Ma range of shaving attachments for automatic lathes includes Gildemeister, Schutte, Wickman and Mori-Say automatic lathes.

Thread chasing attachment

On multi-spindle automatic lathes, on pieces not reachable from the front, the solution adopted to create threads is the use of a fast GR1 thread chasing device. The thread chasing attachment is an alternative to other equipment such as the thread milling attachments and tangential thread-rolling heads. The thread chasing attachment has several variations, in some cases also suitable for internal threads.

The De.Ma range of thread chasing attachments for automatic lathes includes Wickman, Gildemeister, Schutte and Mori-Say automatic lathes.

Frontal milling attachment

Available in both fixed and rotating versions, the frontal milling attachment is a specific equipment for frontal milling of plans or grooves and its use is adaptable, subject to specific modifications, to different types of material. The head of the equipment (rotating or, alternatively, fixed) is installed on the milling spindle which runs on the lathe slide. The De.Ma range of frontal milling attachments for automatic lathes includes Mori-Say, Wickman, Gildemeister and Schutte multi-spindle automatic lathes.

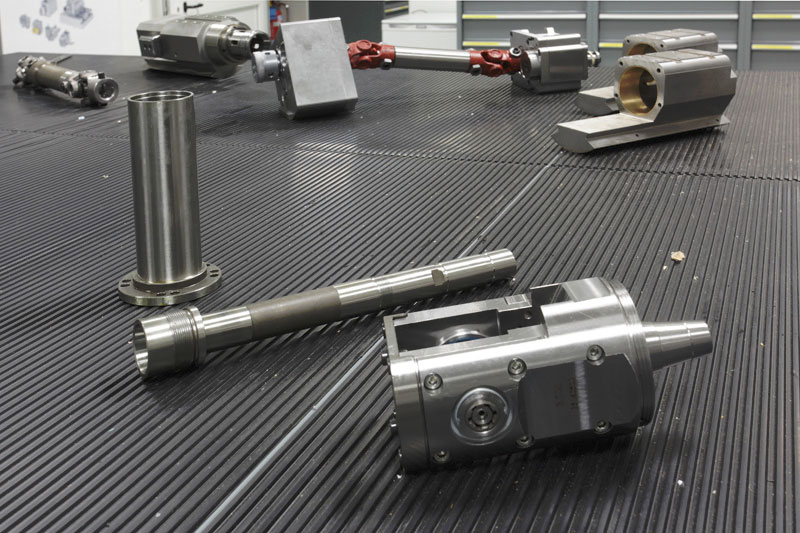

Pick-up spindle

The pick-up attachment is an equipment mounted on the lathe central support, its function consists in taking workpieces rotating on the main spindle of the machine. This is necessary for any subsequent process and anticipates the cutting phase of the piece.

The De.Ma range of pick-up attachments for automatic lathes includes Wickman, Schutte, Gildemeister and Mori-Say automatic lathes.

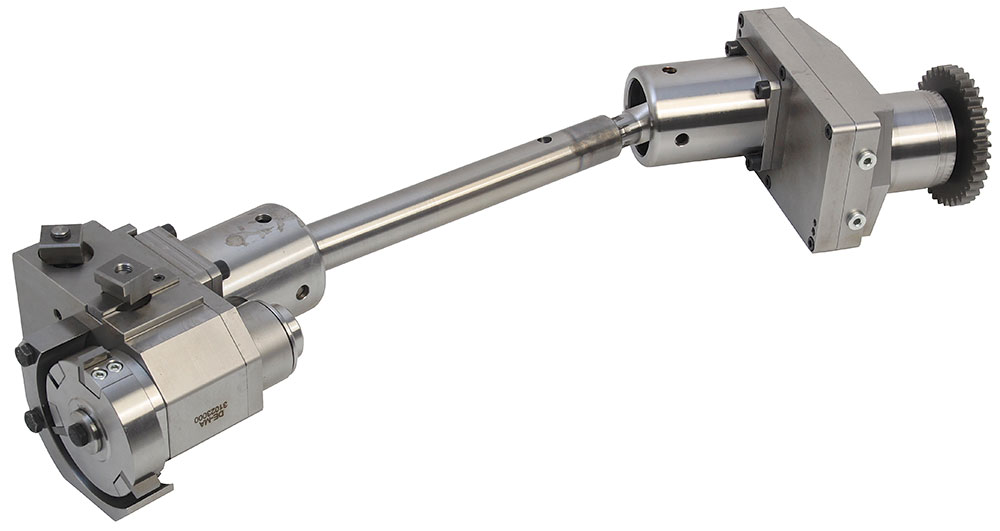

Polygon generating and thread milling attachment

Sometimes during milling operations polygons, threads and hollows are required. On these occasions the choice is the Polygon generating and thread milling attachment which tool (in the cases of milling and polygon) rotates in the same direction as the main spindles with the speed ratios 1: 1 and 1: 2. Making a hollow on spherical pieces, on the other hand, happens with a rotation in the opposite direction to the main spindles.

The De.Ma range of Polygon generating and thread milling attachment for automatic lathes includes Wickman, Gildemeister, Schutte and Mori-Say automatic lathes.

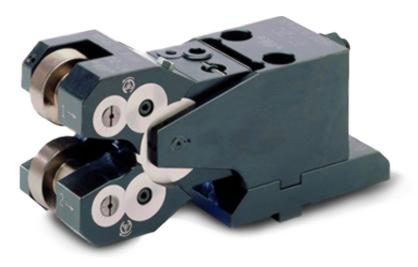

Thread rolling attachment

The production of threads can be made, in some cases, with the thread rolling attachment. This device uses the work of rollers operating in a tangential position to the piece. The plastic deformation obtained by compression increases the resistance and finishes of the surfaces.

The De.Ma range of thread rolling attachments for automatic lathes includes FETTE T18 T27 and others for multispindle lathes such as Wickman, Gildemeister, Schutte and Mori-Say automatic lathes.